Cars are noisy things, and they can make all sorts of sounds. From the whoosh of a turbocharger to the pops and crackles of the exhaust, or the banging tunes on your radio. These are the good sort of noises that put a smile on your face. Although occasionally, a car makes nasty sounds like a lifter tick that makes your heart sink to the ground.

Now, you might just dismiss that slight tapping or ticking noise coming from your engine. “It’s probably nothing”, you might think to yourself to calm the storming anxieties in your imagination. You’d probably just keep driving along, and hoping the lifter tick would suddenly go away. Or, you might turn up the volume on your Spotify playlist a bit louder to drown out the noise.

After all, tap dancing would be far more pleasing to listen to than your engine tapping away loudly. We all know that odd noises like these are often a bad sign that big, expensive repair bills are in order. Lifter tick can be a very easy and painless fix. But ignore it for long enough, and it will happily cost you a kidney’s worth. So, read along our lifter tick guide to learn more.

- Hydraulic Valve Lifter

- Symptoms Of Bad Lifters

- Is It Safe To Keep Driving?

- Causes Of Lifter Tick

- Fixes For Loud Lifter Tick

- Prevention Tips & Tricks

- Final Conclusion

- Frequently Asked Questions (FAQs)

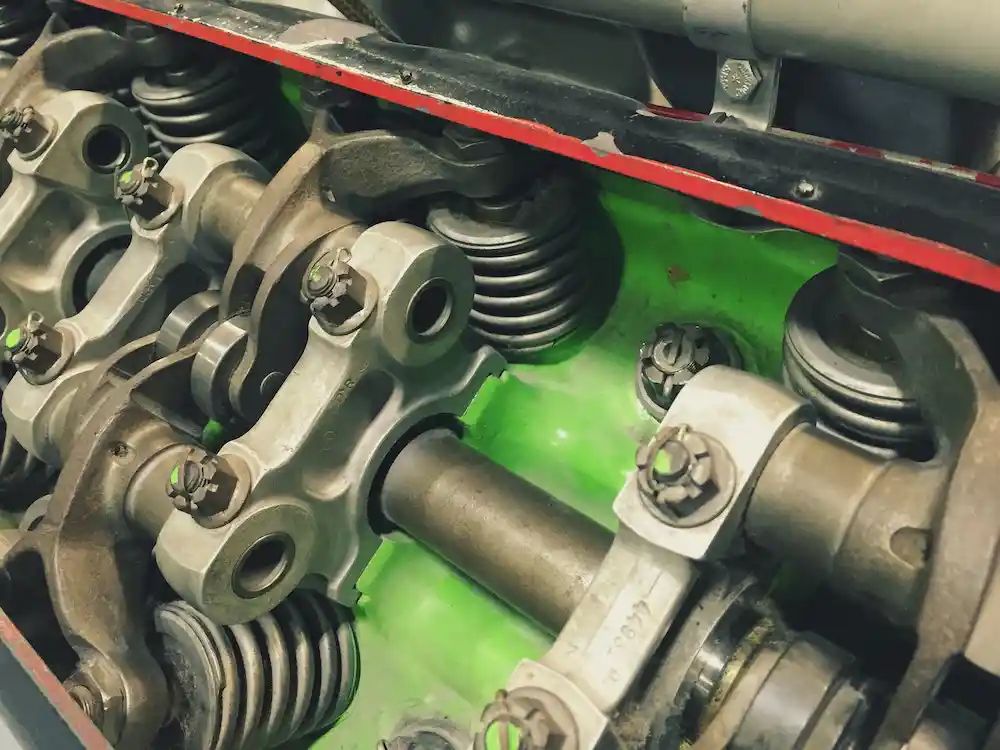

Lifters Engine

Before we can understand more about what a lifter tick is, we should learn more about what a lifter does. This part of the engine goes by many names. It can be called a ‘hydraulic tappet’, ‘hydraulic valve lifter’, or the ‘hydraulic lash adjuster. As we know, a car’s engine is a very complex device, and it has many moving parts working together.

It is crucial that these parts work harmoniously and in unison. Ensuring that all the engine’s components work together as intended is critical in maintaining performance, efficiency, and durability. One such component that needs to be working in its most optimal state is the tappet. The engine tappet, or valve lifter, is what connects the engine’s valves with the camshaft.

The valve lifter works to transfer the rotational motion of the camshaft into vertical motion that opens and closes the engine valves. This is then what controls the intake of fuel and air into the combustion chamber. It also controls the exhaust of the combustion process out of the engine’s combustion chamber, and the process repeats.

Hydraulic Lifters

Traditionally, older cars have solid valve lifters or engine tappets. These often require regular adjustments. This is in order to ensure that a small clearance exists between it and the valve, through the engine’s rocker arm or pushrod. This clearance prevents the valve lifter from binding with the other components, owing to the heat from the engine.

Naturally, doing so increases wear and tear on the valve lifters before they can reach their optimal temperature and the normal temperature of a car. Moreover, it’s also noisier, as the parts would make contact with each other while in operation. Hydraulic valve lifters were designed to help alleviate this problem. Its ultimate goal is to ensure a zero valve clearance, or gap between the valve lifters, and the aforementioned rocker arm and pushrod.

This zero-gap would thus allow the rest of the engine’s valve train to operate smoothly, quietly, and without excess wear. Subsequently, this means that engines fitted with hydraulic valve lifters do not need periodic calibrations. A hydraulic valve lifter’s construction consists of a steel cylinder, hollowed out by a piston, which is then held by a spring.

The hollow chamber is what allows engine oil to flow through and fill the valve lifter. As is the nature of hydraulics, the oil is what regulates the movement of the valve lifter. It pressurizes or depressurizes depending on the movement of the engine valves, and the camshaft. The flow of oil is important to ensure that the valve lifters work optimally in ensuring zero valve clearance.

Bad Lifter Symptoms

We’ve now understood more about what an engine’s valve lifter is, and how it works. Moreover, we’ve also come to realize how important it is in the inner workings of an engine. But before we can start diagnosing the issue further, you should need to know more about the symptoms. These are clear signs that you can sense, to know if your car is suffering from a lifter tick.

In the case of a lifter tick, the most obvious tell-tale sign is the tapping or ticking sounds you hear from the engine. The sound itself can vary in its rhythm, increasing in volume and frequency along with engine revs. Often, the higher the RPMs, the louder and quicker the tapping will be. However, aside from the obvious noise, there are also some other symptoms of lifter tick.

1. Check Engine Light

Other signs of a lifter tick can include the ‘check engine‘ illuminating on your instrument cluster. Cars have various sensors to detect that their many moving parts are working as intended. When faults occur, such as a lifter tick, the check engine light might appear to warn you.

2. Engine Misfires

A damaged or broken valve lifter can badly disrupt the engine’s combustion process. This is regarding the mixture and subsequent burning of fuel and air. This can then cause the engine to misfire, which is another symptom and consequence of a lifter tick. Misfires can result in decreased performance, such as sluggish acceleration.

How Long Can You Drive With Bad Lifters

Often when coming across problems with your car, we tend to just ignore it at first. This is understanding that problems can always be complex and expensive. So, we tend to take the path of simply ignoring our problems, and hoping they’d go away after a while. Most people tend to ignore the lifter tick and keep on driving as if it never happened.

Should you keep on driving while your car is suffering from a lifter tick? Absolutely not. We do not recommend that you keep driving a car that has a lifter tick. So, if you’re already driving, and hearing that dreaded tapping sound, pull over as soon as you can, and call for a tow truck. If you’re just about to leave the driveway, then turn back around and park your car safely.

After that, you can give a call to your nearby workshop or dealership to see about having it checked out. Lifter tick can be a very simple fix if addressed quickly. As always, never ignore the odd noises and sensations from your car. It might be disheartening to have to pay for a fix. But if you continue to ignore faults while they’re just starting out, it can lead to more catastrophic repair bills later on.

What Causes Lifter Tick

“But what is making my engine do all those loud ticking sounds”, you might ask. Well, we can now get into looking deep at the root causes of engine lifter ticks. Understanding the cause can better place us to know what fixes need to be done, and what they’ll eventually cost.

Well, here we have a list of the common causes that result in valve lifter ticks, in order of severity.

Lifter Tick Causes #1: Low Engine Oil Level

As we’ve learned earlier, engine oil is a key part of the inner workings of your valve lifter. It, just like most other moving parts, requires constant lubrication to avoid excess wear and tear. Moreover, hydraulic valve lifters require oil as a medium to function properly.

Nominal amounts of engine oil guarantee that a valve lifter can maintain its lifting power. As such, insufficient engine oil can cause problems like lifter tick, or more serious ones down the line. This is because the valve lifters are constantly rubbing against other moving parts.

Or, that the hydraulics are not functioning as needed, due to insufficient fluids. Thankfully, most cars have a ‘low oil’, ‘oil’, or ‘low oil pressure‘ warning light that illuminates your car’s dash cluster.

Lifter Tick Causes #2: Dirty Engine Oil

Similarly, with low engine oil, dirty oil can also cause a lifter tick. Engine oil is not intended to last forever, and as with all your car’s liquids, needs changing. Your car’s manufacturer should have a service interval for engine oil. After a while, engine oil can pick up dirt, and grime, or thicken itself like sludge.

Remember, valve lifters need engine oil as lubrication, and to ensure good lifting power. Dirty engine oil can clog up the valve lifter, thus resulting in the same situation as having insufficient levels of oil. This results in the valve lifters not receiving the optimal amounts of fluids to function and avoid wear and tear.

Lifter Tick Causes #3: Using The Wrong Oil Viscosity

This, once again, highlights the importance of engine oil in ensuring that your valve lifters work seamlessly, and without problems. Indeed, it can be possible for you to choose the wrong type of engine oil for your particular car. So, be sure to not just pick up any old bottle of oil from the shelves next time you’re doing a top-up.

Just like dirty engine oil, the viscosity of the fluid is important in ensuring that your valve lifter functions as intended. Engine oil that is too thick or thin can affect the flow of the oil within the valve lifter. Every car manufacturer uses different engines and thus differing sets of valve lifters.

Therefore, they each have their own recommended engine oil that pairs best with your car. Maintaining an ideal viscosity will help to prevent lifter tick. It will also help to ensure that the rest of the engine will work as smoothly as intended.

Lifter Tick Causes #4: Faulty Engine Valve Lifter

As with every moving part, an engine’s valve lifter is subjected to immense stresses and strains while under use. Consequently, it will naturally wear out over time and will require a replacement. Aside from engine oil, a faulty valve lifter will also cause the lifter to tick over time.

Failing valve lifters can be caused by a number of issues. For one, valve lifters have a set lifespan, and will degrade in their integrity over time. If your car is old or has accumulated a high mileage, then it might need its valve lifter replaced. Alternatively, valve lifters could also fail due to poor maintenance.

Lackluster maintenance includes not changing the engine oils regularly or using low-quality engine oil. Taking poor care of your car, and not keeping on top of its servicing intervals can eventually cause problems like lifter tick.

Lifter Tick Causes #5: Misaligned Lifter Spacing

As we’ve learned much earlier on how valve lifters work, spacing is very important in its function. There needs to be a small amount of clearance between the valve lifter, and the other interacting parts. This includes the camshafts, and the pushrod or the rocker arm.

Poor balancing on the spacing around the valve lifters can also cause lifter tick. If there is too much clearance, the lifter won’t be able to make contact with the camshafts or pushrod. This will cause the lifter to rattle around loosely. Meanwhile, too little clearance can cause damage to the valve.

This is due to the valve stems expanding in size as it absorbs heat from the engine. If too much heat is transferred between the lifter and the valve stem, the ensuing damage will cause a lifter tick. It is important to make sure that your car’s valve lifters are adjusted to their most optimal positions.

Lifter Tick Causes #6: Bent Pushrod

The pushrod is one of the key components of an engine. Its primary function is to operate the intake and exhaust valves of the car’s combustion chamber. Therefore, pushrods are designed to be among the more robust parts of a car. However, it can be subjected to damage, if not cared for.

This is especially so if the car is being pushed too hard, or driven too excitedly. The increased strain can cause immense wear and tear, which could eventually bend the pushrod. The bending can then result in prematurely wearing out the valve lifters, which would cause a lifter tick.

Lifter Tick Fix

Having now known and understood the key causes of lifter tick, we can discuss more on how to get it fixed. As mentioned earlier, your car’s valve lifter ticking can be as easy of a fix as having its engine oil changed. However, if you’re not attentive and careful, it can very quickly escalate into a very expensive repair job.

Here’s a list of fixes to help quieten down your engine, and solve lifter tick for good.

1. Top-Up Or Replace Engine Oil

We’ve learned so far that maintaining your engine oil is key to making both your car and its valve lifters happy. Otherwise, it could lead to problems that will eventually cause a lifter tick. Engine oil plays a key role in lubricating the moving parts within and around your valve lifter. Moreover, hydraulic valve lifters require engine oil to function properly, and to maintain its lifting power.

If your engine oil is running low, it can be evident with a ‘low oil’ warning light on your instrument cluster. Alternatively, you can very quickly check the engine oil reservoir within your engine compartment. If the oil level is below that what the dipstick says is the bare minimum, then have it topped up.

2. Find And Use The Right Oil For Your Car

However, remember to always consult your owner’s manual, or call up your local dealer to find the exact engine oil recommended for your car. There are many different types of engine oil. The most important variable to look out for is the viscosity of the oil itself. This is important in the context of the valve lifters, as oil needs to flow smoothly through it.

This will depend on your individual car. You will also have to take note of the weather around you. In the cold winter, you are recommended to find thinner or less viscous oil. In the warmer summers, you should find thicker, and more viscous engine oil. Alternatively, you can choose to purchase all-season engine oils (multigrade – most new cars use this anyway), which are a bit more expensive.

3. Replace Engine Oil Filter

Speaking of engine oil, it is also important that you make sure the flow of oil within your car remains clean. We’ve discussed earlier how dirty oil can clog up the flow to and between your valve lifters. One of the parts within a car that makes sure oil remains free of dirt or debris in the oil filter.

Just like any other parts within a car, the oil filter will eventually need replacing. A good oil filter should be able to prevent dirt, or any other debris from accumulating in the engine oil. This will ensure that the flow of oil remains smooth, clean, and uninterrupted. Doing so will help to prevent lifter tick from happening.

4. Use Engine Oil Additives

On the subject of oil, you can also consider additives to ensure the cleanliness of the oil. Add to that, a good splash of oil additives can also clean the components that the engine oil has to lubricate. This includes the valves, the rocker arms, pushrods, and the valve lifters, as well.

Oil additives keep the engine oil clean, and ensure a smooth flow through the rest of the engine. Your owner’s manual should be able to point out some of the best oil additives that are recommended for your car. Adding this along with your engine oil might not just help to fix the lifter tick, but could also prevent it from happening again.

5. Replace Or Adjust The Valve Lifters

If worst comes to worst, the valve lifters might break, and will need replacing. If even just one breaks, it’s often recommended to replace all your valve lifters as well. This is because just one faulty valve lifter can cause added strain and wear on the others. Replacing valve lifters is expensive, and can depend on what car you’re driving, and the engine that it has.

Not only are the parts very costly, but replacing valve lifters is also a very labor-intensive job. Altogether, the price range can vary widely, and we recommend that you call up a mechanic to get a more precise quote. Generally, the average repair bill for replacing valve lifters can be anywhere from around $300 to $1,000. However, don’t be surprised if the bill rises to $1,500 or higher.

This underscores the importance of making sure you service your car regularly. Alternatively, the valve lifters only need a simple adjustment. Once again, this is related to the precise clearance needed between the valve lifters, camshafts, and pushrods. Owing to how tight the tolerances can be, we recommend that you find a professional to help you with this task.

6. Replace Pushrods Or Rocker Arm

If the pushrods or rocker arm are damaged, it can cause a lifter tick. The only way to fix this is by replacing them with brand new parts. Just like replacing the valve lifters, this is once again another pricey, and labor-intensive work. We also recommend that these replacements are done by a qualified technician. Although, a highly knowledgeable car owner could do this at home.

The parts and the related kits for either a pushrod or the rocker arm are not cheap either. The prices once again vary, depending on the model of your car, and the engine that it has. But in general, we can expect an average of $600 to over $1,000 for replacing pushrods. Meanwhile, replacing the rocker arms can cost anywhere between $500 to $1,500 on average.

7. Check for Damaged or Worn Camshaft Lobes

A damaged or worn-out camshaft lobe can mimic the ticking sound that comes from faulty valve lifters. The camshaft has multiple lobes that push against the valve lifters, making sure the valves open and close properly. If a lobe is worn out, the valve will not operate efficiently, leading to ticking noises. To inspect for this issue, you might need a mechanic’s expertise. If the camshaft is the culprit, replacing it is the solution.

8. Ensure Proper Valve Spring Tension

Valve springs ensure that the valves return to their closed position. If a spring loses its tension or becomes damaged, it can cause the valve to operate incorrectly, leading to a lifter tick. Inspecting and replacing the weak or damaged valve springs can help eliminate the noise. Remember, proper tension in these springs is vital for optimal valve operation.

9. Inspect for Lifter Bore Wear

The lifter bore is the housing where the valve lifter resides. If this bore becomes worn out or damaged, it can cause the lifter to operate inefficiently, leading to the ticking noise. Have a mechanic inspect for lifter bore wear. If wear is discovered, you may need to repair or replace the affected engine component.

10. Try Different Fuel Grades

Believe it or not, the grade of fuel you use can affect engine noise. Some engines are designed to operate on higher-octane fuels. Using a lower grade can cause knocking or ticking. Before making the switch, consult your vehicle’s manual to ensure you’re using the recommended fuel grade. If you’ve been using a lower grade, consider upgrading to see if it resolves the issue.

11. Regular Engine Maintenance

It might sound cliché, but regular engine maintenance is key. This doesn’t only mean oil changes but also includes checking belts, pulleys, and other moving components. Over time, belts can fray or pulleys can become misaligned, both of which can produce ticking or other noises. Keeping everything in check and replacing parts as they wear out can prevent lifter ticks and other related issues.

12. Inspect Other Potential Noise Sources

While the lifter tick is distinct, other engine components can produce similar noises when they malfunction. Components such as the timing chain, timing belt, and even some accessories driven by the serpentine belt can emit ticking or knocking sounds. Have a mechanic inspect these areas if you’ve addressed the valve lifters and still experience noise. Identifying the exact noise source ensures accurate repairs.

In conclusion, the lifter tick, although common, is a sign that some part of your engine requires attention. Addressing it promptly can prevent more extensive damage and ensure your engine runs smoothly for miles to come. Regular maintenance, thorough inspections, and seeking professional advice when in doubt can go a long way in keeping lifter tick at bay.

How To Prevent Lifter Tick

Right, so you’ve probably been left bittersweet by having your car’s lifter tick problem fixed. On the one hand, your car’s engine is running smoothly, and no longer sounds like it’s tap dancing. On the other hand, you’ve probably burnt a huge hole in your wallet trying to fix this. You’re probably wondering to yourself, “how could I ever prevent this from happening again?”

On the bright side, at least, we’ve learned that lifter tick is easily preventable. In fact, the best prevention method works just as well as with most other car-related problems and heartaches. That is, to simply ensure that your car is well maintained, and that regular servicing schedules are adhered to. Remember, a lot of issues can be prevented by keeping your car in tip-top shape.

This advice goes for any sort of car, type, and from every brand. It works just like keeping a healthy diet or practicing regular exercise for your body. Every carmaker will have outlined a reasonable servicing schedule for each vehicle. This depends on how long they’ve been driven, and their mileage. By simply having it serviced, you can prevent a lot of stress down the road, including lifter tick.

As we’ve already learned so far, lifter ticking’s most common cause is the state of the engine oil. Engine oil needs to be changed regularly, and it’s part of your car’s servicing program. By keeping the oil clean, and at sufficient levels, the engine and its many parts can remain lubricated and cooled. This alone can most easily make sure a lifter tick never needs to happen.

Lifter Ticks: In Conclusion…

Thus far, we’ve been able to learn what an engine valve lifter is, and how it works. We’ve even gone through more on the cause of lifter tick, and how to solve them. We hope then, that this has been helpful in diagnosing that annoying tapping sound you might’ve heard resonating from your engine. It’s almost always a small problem, but it’s also deserving of your attention.

We cannot stress enough how easily lifter tick problems can be fixed and prevented. However, continually ignoring those odd noises and sensations will quite easily cause catastrophic damage to your engine. Always be attentive to your car’s condition, and practice a habit of servicing it regularly. If you’re mindful enough, you might never, ever have to hear that ticking noise again.

Lifter Tick Essential Knowledge

- Engine noises that are not normal can indicate potential problems that need to be checked out immediately.

- Rhythmic ticking or knocking sounds in the engine are a cause for concern and should be diagnosed by a professional technician.

- A lifter ticking sound could mean that there’s a problem with the lifters that pump oil to transfer the motion of the camshaft into the movement of the valves.

- Lifter noise should be checked out because if neglected, it can ruin a camshaft or the entire engine.

- Exhaust leaks can cause sounds similar to lifter ticks, but a professional technician can quickly diagnose and fix the problem.

- A rod knock, which emanates from the lower part of the engine, is a serious problem that can cause engine failure and requires immediate attention.

- Piston slap can occur when a part of the piston skirt breaks off, and while some engines may still run fine, it’s best to get a technician’s opinion on what to do next.

- A loose torque converter can cause lower-end noises, but it can be fixed by tightening bolts.

- Neglecting engine noises and running the vehicle until it dies can cause irreparable damage to the engine.

- Regular engine maintenance and repairs can help ensure the safety and reliability of the vehicle on the road.

Lifter Ticks: Frequently Asked Questions (FAQs)

If you’re still curious to learn more about lifter tick, perhaps our FAQs here might help out…

What Is A Lifter In An Engine

A lifter is also otherwise known as a hydraulic tappet, hydraulic valve lifter, or hydraulic lash adjuster. Essentially, what an engine tappet or valve lifter does is connect the engine’s intake and exhaust valves with the camshaft. What this means is that per the rotation of the camshaft, the lifters are responsible for transferring the rotational motion of the camshaft into the vertical motion of the intake and exhaust valves opening and closing. Thus, allowing your engine to control the intake of fuel and air into the combustion chamber. While at the same time, exhausting combustion by-products and fumes out of the engine.

How Do Hydraulic Lifters Work

Older cars usually feature solid valve lifters, which would often require frequent adjustments to ensure a tight clearance between it and your engine’s intake and exhaust valves. Later on, hydraulic lifters were created to solve this problem by ensuring that there’s zero valve clearance between the lifters, as well as your engine’s pushrod and rocker arms. Hydraulic lifters consist of a steel cylinder that features a hollow piston within them, which allows the motor oil to flow through. The oil can thus use hydraulic pressure to regulate the movement of the hydraulic lifters, while also maintaining that zero valve clearance.

Why Is My Car Ticking

If you’re hearing a ticking sound from your car, one likelihood is that it’s coming from your engine’s valve lifters. This tapping or ticking sound will often tick faster and louder once you reach higher RPMs. Lifter ticks spawn due to numerous issues, mainly attributed to your engine oil. Running old, dirty, worn-out, a low amount or the wrong type of engine oil can cause the ticking to appear. Beyond that, the valve lifters themselves might be faulty, or there’s an issue with their spacing and clearance. Otherwise, your engine’s pushrods might be bent, which is a very serious sign.

How To Fix Lifter Tick

Most of the underlying causes for why your engine is ticking in the first place can be blamed on your motor oil. Running contaminated, burnt, a low volume, or the wrong viscosity of engine oil will very quickly prompt a lifter tick to appear. Therefore, one easy way to fix lifter ticking is by changing or topping up the oil, as well as ensuring that you’re using the right type of engine oil. While you’re there, make sure that you also swap out the oil filter. If not, and if there’s damage to the valve lifters, rocker arms, or pushrods, you’ll have to replace or re-adjust them.

How To Clean Lifters Without Removing

With time, valve lifters can get clogged up or sticky with extensive use. Hence, why it’s crucial to have them cleaned and restored, especially if you’re keen to solve issues like lifter tick. Although most experts recommend removing them before cleaning, you could still easily clean the valve lifters without having to remove them from the engine. Often, this would involve adding an engine flush cleaning solution into the oil reservoir and running the engine for a bit to let it circulate. Once it’s had time to work at cleaning your engine (including the lifters), drain out the solution (with the oil), and perform an oil change. This includes swapping out the oil filters. Then, add some new oil, and that alone should help to clean the valve lifters without having to remove them.