Are you experiencing some unpleasant noises coming from the valve covers? If this is the case you are highly likely to have a damaged rocker arm. This component is crucial in delivering proper combustion. But unfortunately, sometimes when the rocker arms are exposed to a lot of stress they can go bad and develop issues. In this case, the best thing for you is to learn the rocker arm replacement cost in order to know what you could expect for the repairs to cost. But you shouldn’t worry because we are going to cover everything.

Troubleshooting is key when it comes to car-related problems and you must learn how to troubleshoot issues. Especially problems like this with the rocker arms. These components are fairly simple to diagnose and find the culprit. That’s why you should not be afraid to take action when it comes to wrenching on your car.

The rocker arms are located right under the valve covers and they are easily available for you to check if they are bad or not. And later in this article, we are going to explain how you can do this work on your car. After reading this article you will know how to diagnose this problem.

In this article, we are going to learn what are rocker arms and what is their task. Then we will cover the symptoms of a bad rocker arm and also how to diagnose a bad rocker arm. Then we are going to cover the rocker arm replacement cost. The cost is key in determining your budget and how much you can spend on parts. So, let’s dive into the article.

What Are Rocker Arms?

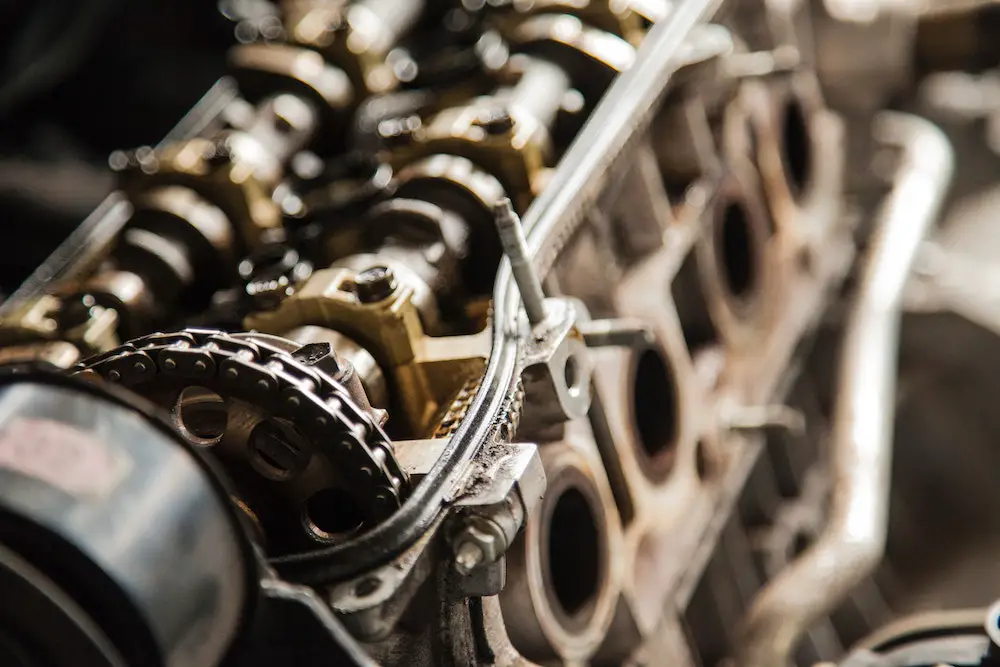

Rocker arms are engine components that are located on the top of the engine. More precisely they connect the pushrod and the valve spring. How they work is pretty simple to explain.

The rocker arms are pushed by the pushrods which are located on each of the cylinders. When the rockers are pushed by the pushrods, they press the valve springs. Then the valve springs open and close the intake and exhaust valves. But what pushes the rods in order for them to cause the rockers to move? The pushrods are pressed by the camshaft that is located in the center of the engine.

There is a separate rocker arm for each intake and exhaust valve. Making the total rocker arms on one bank that has 4 cylinders to be 8 rocker arms in total. Remember, one rocker arm for intake and one rocker arm for the exhaust valve.

When the rocker arms fail, they no longer make this work possible of opening and closing the valves properly and this translates into numerous symptoms. These symptoms of bad rocker arms can be pretty simple to diagnose and we are going to cover them in detail later in the article.

Then after we are going to cover the rocker arm replacement cost in order for you to have a better perspective of what you can expect when you are having a bad rocker arm in your vehicle’s engine. This will be the key to solving the problem permanently. We are also going to explain how you can replace the rocker arms all by yourself without the aid of mechanics.

Remember that this job is fairly easy and will not require a lot of experience if it’s only one rocker arm that was affected.

Types Of Rocker Arms – Rocker Arm Replacement Cost

We have covered the role of the rocker arms and now let’s see what are the types of rocker arms that are out there. Each of them has their own application and role for which they were designed to fulfill. Some of them were designed for regular gas engines, some of them were designed for racing applications. While some were designed for big heavy machinery.

Stamped Steel Rocker Arms

The most basic type of rocker arms are the stamped steel rocker arms. This type is the most prevalent in the car world and the vast number of cars are using stamped steel rocker arms. This is the case because they are easy to manufacture and extremely cheap. A big press is basically stamping them out from large sheets of steel. This also makes them more prone to failure and they can fail more often than other types of rocker arms.

But the cheaper manufacturing process also makes the rocker arm replacement cost a lot cheaper compared to other types of rocker arms that we are going to cover next.

Aluminum Rocker Arms – Rocker Arm Replacement Cost

Aluminum rocker arms are a type of rocker arms designed specifically for racing applications. These rocker arms are extremely light and durable. They are able to handle a lot more power than regular rocker arms that are made out of stamped steel.

This makes them perfect for high-performance applications and they can improve the overall horsepower rating. Using aluminum rocker arms will improve your horsepower numbers by a big margin. But the downside of these rocker arms is that they are rather expensive. They can cost much more than regular stamped steel rocker arms.

Cast Iron And Forged Carbon Rocker Arms

And the last type of rocker arms are the cast iron rocker arms and the forged carbon rocker arms. We add these rocker arms in the same group because they have similar roles and they are widely used in heavy-duty applications. Namely, heavy-duty trucks and diesel engines that have high torque numbers.

A regular stamped steel rocker arm would quickly fail when exposed to these great forces that are involved in hauling heavy objects. That’s why cast-iron rocker arms are used and from recent years the forged carbon rocker arms are gaining a lot more traction. They offer quite a lot for how they are designed.

But this also means that forged carbon rocker arms cost quite a lot more than regular cast iron and stamped steel rocker arms. Making the rocker arm replacement cost quite expensive for these applications.

Symptoms Of A Bad Rocker Arm

When the rocker arms start to fail or they have failed. They start to develop symptoms of a bad rocker arm. Some of these symptoms are mild. While some of them are more pronounced and will show some loss in performance of your engine. This can be frustrating to deal with and you might end up frustrated. But you shouldn’t panic and make sure that you diagnose the issue properly.

In this chapter, we are going to cover all of the symptoms of bad rocker arms in order for you to have a clear understanding of the issue and to be able to diagnose the problem quickly and effectively. Then we are going to cover the rocker arm replacement cost. So, which are the symptoms? Let’s find out.

Check Engine Light

The check engine light is one of the first symptoms that you will experience if you have a bad rocker arm. This will only be the case if your engine is connected to a computer. If you run a classic V8 that is carbureted, you won’t experience this symptom in your car.

The check engine as light doesn’t mean much and you will not have a clear input on what is wrong. But it will tell you that you have an issue and this issue needs solving.

You will have to connect the car to an OBD2 scanner tool. This tool is going to tell you everything you need when it comes to this problem and more. These scanners are lifesavers and will save you thousands of dollars in the long run. That’s why it is recommended for every car owner to have one of these scanners. Having the input will help you out with your car getting misdiagnosed by incompetent mechanics. Thus, saving you thousands on possible repairs that will come up.

Specifically for this problem, you are highly likely to experience the P2646 error code. This code means that the rocker arm “A” actuator system performance. This error code means that the rocker arm is stuck and needs checking. The problem prevails on cars that have seldom oil changes because these problems are mostly caused by sludge buildup from dirty oil. But also, can mean that the rocker arm is damaged.

Other codes connected with the rocker arm are the P2647 for the rocker arm oil pressure switch and the P2662 for rocker arm “B” actuator stuck at the system bank two.

These errors are going to tell you which bank of the engine you should focus on in order to resolve your problem.

Engine Misfires And Ticking Noises

Engine misfires as well can indicate damage to the rocker arms. When the valves are not opening and closing the misfires are unavoidable and you will start to experience them more and more often.

This is the case because the rocker arms are hitting the valves. So, if the rocker arm has damage to the section where this operation is done you will start to experience misfires.

These misfires will resemble ticking or another type of sound that you will notice when the engine will be running. All these sounds will come from underneath the valve covers and you will be able to easily diagnose these issues if you remove the valve cover. How you can perform this work we are going to explain later in this article.

Nevertheless, engine misfires can also be felt at the back of the exhaust. If you listen well, you will notice some pops coming out from the exhaust pipe. These pops will be uneven and this action will not resemble a natural work of an engine.

There are two options on the table. Either the rocker arm is damaged and doesn’t deliver the right amount of performance making the engine misfire. Or there is a different problem and that is the misadjusted valves issue.

Also, when the valves are misadjusted, the engine will start to misfire. For some engines, the valve adjustment work is recommended to be performed every 60,000 miles. So, if your engine valves were never aligned and adjusted, then this is likely your problem.

Misadjusted valves can also damage the rocker arms as well. Their work will not be even and they might experience some unexpected wear and tear on them. The best is to diagnose the problem as soon as possible.

Physical Damage To The Rocker Arms

The rocker arms can also get damaged throughout the years of service and develop cracks and wear and tear issues. The physical damage can only be inspected with a visual inspection.

If you notice that your rocker arms are missing some metal and are flattened out at the point where they are hitting the valves. Then this means that the rocker arms are due to be replaced.

This damage will affect the timing and will cause your engine to misfire. When the valves are not aligned properly, misfires are unavoidable.

That’s why you need to diagnose the problem and how you can diagnose the issue we are going to cover later in the article.

Nevertheless, if you have also done some modifications to your car, it can also cause physical damage to the rocker arms.

That’s why there are performance rocker arms on the market. These performance rocker arms are made of lightweight durable aluminum and can withstand the sheer amount of force that is involved in the combustion process.

When you do performance upgrades like new aftermarket camshaft or pistons. You should always go aftermarket with the rocker arms and rods. These high-performance parts will guarantee that you will not experience wear and tear of the rockers and the aftermarket components will deliver a lot more performance to the table as well.

Bad Engine Performance And Stalling Issues

Bad engine performance will also be present when you have a bad rocker arm issue. The issues concerning engine performance will be most pronounced on vehicles that have a lower amount of rocker arms. Which in other words translates to the lower number of cylinders.

Every cylinder has two rocker arms. And if the rocker arms on one or two cylinders fail on a smaller displacement engine like a straight-4 engine, for example, will take a lot from its performance and will basically make the car undrivable.

The engine will start to stall and lose power. This will be the case because the valves will not open and close. When the valves don’t open and close at the right time you get misfires or bad combustion.

This bad combustion will make your engine not function properly. Not only on small engines but also some bigger displacement engines could suffer the same symptoms as well. Especially engines that haven’t been checked for a long time.

In worst cases, the engine will not be able to run at all. This will require resolving the problem before you try to start your car again.

That’s why you need to inspect your rocket arms every once in a while. And we are going to explain how you can do that in the next chapter. After we are going to cover the costs when it comes to replacing the rocker arms.

How To Diagnose A Bad Rocker Arm?

In order to diagnose bad rocker arms, you have to have access to the rocker arm itself. The best thing is to remove the valve cover that covers the rocker arms. Wiggle the rockers and see which of them have a play or if they have some visual damage to the rollers.

This will give you a good input on which of the rocker arms are bad. Also, check the material for wear and tear and see if they are worn out at the place where they make contact with the valve stem.

This visual inspection will tell a lot and you will be able to tell which of these rocker arms are bad and then learn more about the rocker arm replacement cost.

If you don’t get clear input from the visual inspection. Start the car with the valve covers removed. Don’t be afraid. Running the engine without a valve cover will not do anything bad.

Now you will be able to tell which of these rocker arms are not doing their job properly. After you notice the rocker that is causing all this trouble your next step would be to look for the rocker arm replacement cost. That is something that we are going to cover in the next chapter where we will elaborate on the costs in order to get this problem solved quickly and effectively.

Rocker Arm Replacement Cost?

Rocker arm replacement cost is relatively affordable. If you do only one rocker that is affected you are likely to pay somewhere between $15 to $50 for the part alone.

Then you will have to pay a mechanic to replace it. The labor is somewhere between $50 to $100 and you will likely be billed more than 2 to 4 hours for this work. This will result in a repair bill of somewhere between $200 to $400 for the repairs if you go to a workshop.

Remember that this repair will also require adjusting the valve clearance as well to adjust your valves to work in perfect harmony.

If you want to replace all the rocker arms and valves it is highly likely to pay somewhere between $100 to $500 for the parts alone.

If you replace the components at a workshop you will be billed somewhere between $1,000 to $1,500 if you run a V8. For example, if you have a straight 4 engine, you will pay a lot less. Since there are half the number of rockers on these engines.

Replacing the rocker at home is also a good idea and a fairly simple job. But you will need to have a valve adjustment tool and a feeler gauge to perform this work in the right way.

We have covered the rocker arm replacement cost. In the next chapter, we are going to explain how you can replace the rocker arms on your engine.

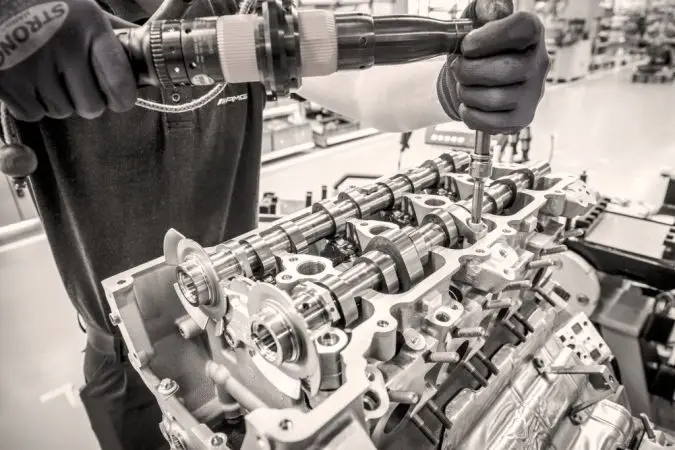

How To Replace A Rocker Arm? – Rocker Arm Replacement Cost

Replacing the rocker arm isn’t a complex process. You will have to get a new rocker arm for your engine and you also going to need a torque wrench to torque the new rocker arm up to spec.

To access the rocker, you will have to remove the valve cover. Then you need to get a torque wrench and then unbolt the bolt that is holding the affecter rocker arm.

Once the bolt is loosed, remove the old rocker arm and replace the rocker arm with the new one. Torque the new rocker arm up to the recommended spec for your engine and you are good to go.

Also, some valve adjustments will be useful to make your engine run without misfires. For this, you will need a valve adjustment tool and a feeler gauge. You need to adjust the rocker arm at the right point to make the valve work perfectly. Then you are good to go.

Can I Continue Driving With Bad Rocker Arms?

Driving with bad rocker arms is a bad idea. Your engine will be misfiring and the chance to stall will be significant. That’s why you should opt to replace the rocker arms. They are fairly inexpensive components and almost anyone can perform this work since they are fairly easy to remove and replace with new ones.

We explained how you can do this work and the rocker arm replacement cost for you to have a better idea of what to expect to pay to replace them.

Facts about Rocker Arms: Symptoms of a Bad Rocker Arm and Repair Costs

- Rocker arms are an important part of some types of internal combustion engines and are located between the pushrod and intake and exhaust valves.

- Pushrods move up and down, opening and closing the exhaust valve and intake valve of the combustion chamber, and power flows from the combustion chamber to the wheels.

- Broken or loose rocker arms can cause the exhaust valves and intake valves to malfunction, leading to engine performance issues and unsafe driving conditions.

- Symptoms of a bad rocker arm include clicking or ticking noises, weak engine performance or stalling, and a check engine light turning on.

- Physical deterioration of the rocker arm can also indicate a problem and should be addressed, as it will cause problems in the future.

- Replacement costs for a single rocker arm can range from $15 to $60, while a kit including other necessary components typically costs between $100 and $500.

- The cost of hiring a mechanic or dealership to replace the rocker arms can range from $500 to $1,500, depending on the vehicle.

- Steel is a good option for economy cars, while high-performance vehicles use aluminum rocker arms and truck engines often require stronger rocker arms made from forged carbon steel or cast iron.

- Troubleshooting by a mechanic or yourself may be necessary to determine the cause of engine noise.

- A check engine light should not be ignored, and a diagnostic scanner should be used to check for any stored codes related to rocker arm issues.

Conclusion – Rocker Arm Replacement Cost

In this article, we covered a lot when it comes to rocker arms and rocker arms issues. We learned what are rocker arms and the types of rocker arms that you might come across.

Then we have covered the symptoms of bad rocker arms and what you could expect when they go bad. The ticking and the misfires are some of the most frequent symptoms of this problem.

After we have covered the rocker arm replacement cost and how much is going to cost you to get this problem sorted. Lastly, we have covered how you can sort this problem by yourself. This will be a good chance to start your wrenching career.