Are you experiencing some ticking noises from the rocker arm and you are thinking that there is a problem with some of these arms? If that is the case, then you are at the right place because there will be a lot to cover on this topic where we will learn everything when it comes to these components.

- What Are Rockers?

- Rocker Assembly

- Manufacturing

- Symptoms

- Replacement

- Cost

- Other Problems

- Conclusion

- F.A.Q

Having a problem like this can be a really frustrating thing to deal with on your pushrod engines. Mainly because these components can produce weird ticking sounds that could be extremely annoying in the long run. At first, you might not even notice them. But soon after you notice it, you cannot ignore it.

This is why you need to try to find a solution to this problem. Finding a solution as quickly as possible will guarantee that you will return your driving comfort back where it should be. So, if you are one of those folks who desperately want to learn the ways to sort out this problem with the rocker arm. Then you are at the right place because there will be a lot to cover.

First, we are going to learn what are rocker arms and why they are so important. Then we will learn from what materials they are made. Then we will cover the symptoms of bad rockers and the rocker arm replacement. After that, we will cover the problem with the rocker arm actuator and see how you can tackle it. So, if you want to learn more about these components, please follow along.

What Are Rocker Arms?

Now before we dive into more complex topics, let’s cover some of the basics and learn what the rockers are in general. Knowing this stuff will help you out understand how you can tackle this issue on your car more easily. If you are already familiar with these components you can jump to one of the following chapters, if not, keep up with us for a bit.

Are these rocker arms like to rock? Well, close enough. These are components that serve a good purpose on your engine.

The rockers are mounted basically on each pushrod engine. A pushrod engine is an engine design that implements pushrods to open and close the valves.

The rockers are there to serve as a bridge between the pushrod and the valve. They transfer the energy and help open and close the valves.

When the rod is pushing, the valve opens up. Once the valve is open then the camshaft spins and releases the pressure on the lifters and the rod retracts with the help of the spring that is on the valve.

Overall, these components have a really simple task and that is to transfer the force from the rods to the valves and do this precisely every time in order for the proper combustion to be achieved.

Rocker Arm Assembly

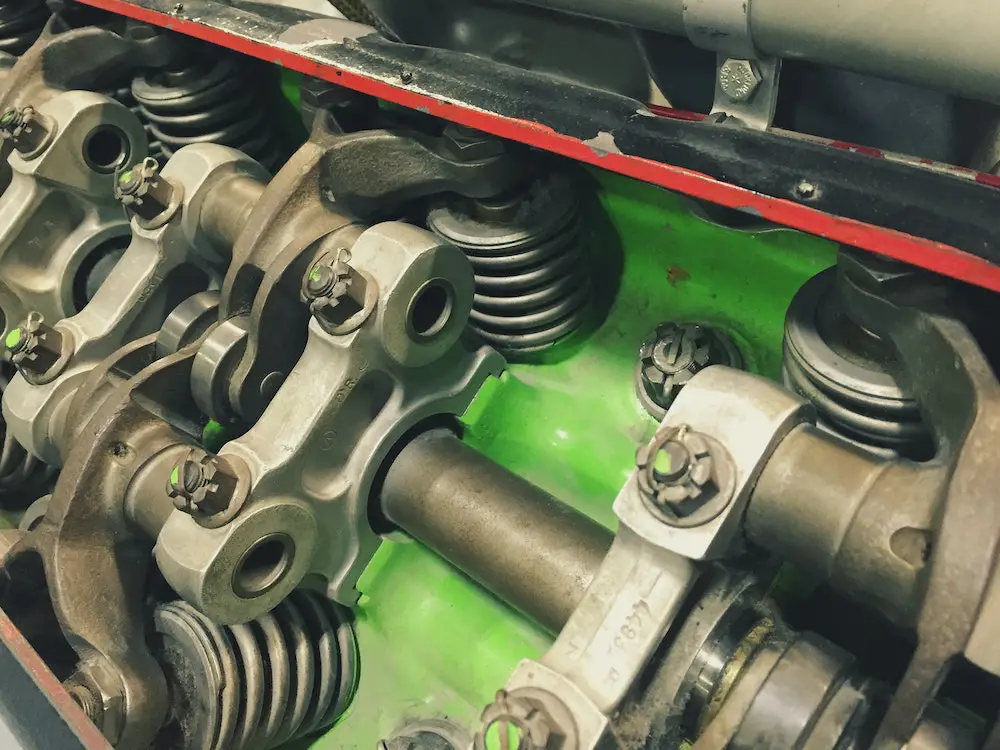

In fact, there is a whole rocker arm assembly. This assembly holds all of the rockers in place, perfectly synchronized. This is a rod on which these components are mounted.

Basically, there are two valves per cylinder, each of these valves has a rocker on it. So, in total there are 8 of these rockers on each bank if you run a V8 engine. And all these 8 rockers constitute a rocker arm assembly.

In total there are two assemblies if you run an engine in a V configuration and one rocker arm assembly if you run an inline engine.

But this shouldn’t always be the case. Most engine manufacturers are mounting the rockers separately and they do not attach them to an assembly. It’s a carmaker’s choice of how they want to design their engine. That’s why it is different from application to application.

It is worth noting that this type of assembly design is only used on OHV engines also known as overhead valve engines, or on SOHC also known as single overhead camshaft engines.

DOHC or double overhead camshaft engines usually do not have a rocker arm assembly.

Why Rocker Arms Are So Important?

We learned what are rockers and we have covered the rocker arm assembly. We concluded that these assemblies constitute a connection to all of the 8 rockers that are mounted on them. This is most notable on Chevy V8 engines, there are also a ton of engines that run rockers and do not include them in a whole assembly. But why these rockers are so important?

Well, they are really important because they transfer the motion from the pushrod to the intake or exhaust valve.

Basically, these components are making all of the action possible when it comes to opening and closing the valves.

Some of them include rollers. These are known as roller rockers and they have a special purpose of reducing friction. So, when the rocker comes into contact with the pushrod it rolls and is lubricated. Reducing the friction and also making sure that these rockers do not wear out prematurely and develop symptoms.

So, many people are trying to upgrade these components with aftermarket roller rocker arms that deliver a much better performance.

From What Materials Are Rockers Made?

Now let’s see from what materials are rocker arms made. This will be extra useful to know if you are on the market for high-performance rockers for your new Chevy 350 build or any other build.

Rockers in the past were made out of cast iron. This made them really heavy and expensive to make. Just imagine that there needed molds to be made for each of these and a single V8 has 16 of them.

This made the whole operation of manufacturing expensive and difficult. They also perform poorly since they are hefty in comparison to stamped steel rockers.

Stamped steel rockers are probably the most widely used type of rockers nowadays. Mainly because this design is so cheap to make. It also drove the cost of engines down significantly. These components are basically made from stamping large sheets of steel by a hydraulic machine.

And they are also very cheap to replace when they go bad. But more on that later when we will discuss rocker arm replacement.

High-performance rockers are made out of aluminum. This material is extremely light and when installed on a high-performance application it is a day and night difference in comparison to the standard rockers.

These also include rollers. So, the material doesn’t wear. This means that with good lubrication, these rollers will last forever. That’s why if you are on the market for aftermarket rockers, you should go for these ones.

Symptoms Of Bad Rocker Arm

Now as we discussed the basics of rockers and the rocker arm assemblies. We can start focusing on the symptoms of a bad rocker arm.

Knowing the symptoms will help you determine if you have a bar rocker on your car. This is why we are going to cover all the different symptoms that are related to this problem in the following chapters.

1. Check Engine Light

The first symptom that we would like to discuss when it comes to bad rocker arm symptoms is the check engine light.

As you probably know, modern engines are all computerized and they include modern systems that can detect when some of the rockers are not functioning as they should. But this check engine light is mostly caused by the rocker arm actuator also known as the rocker arm solenoid that we are going to discuss later on in the article.

What is important is that this actuator causes a P2656 code on some Honda engines. But more on that, we are going to cover later on. What is important is that if you run a pushrod engine, you probably not going to face some of these issues.

2. Ticking Noises From The Valve Covers

The second most common symptom that indicates a rocker arm problem is a situation with the ticking noises that are produced by the engine.

These sounds usually come directly below the valve covers and can be extremely annoying. You will hear a simple tick-tick sound whenever the rockers are in contact with the valve tips and the pushrods if it is a pushrod engine.

This is a clear sign that you need a valve job or a new rocker arm assembly on your car. This is why you should not ignore these symptoms and try to address them as soon as possible.

3. Engine Misfires

The third most common symptom of a bad rocker arm is the misfires that will be really frequent when you have one of these rockers not working as it should.

Especially if it’s damaged, it could impair the engine from working correctly by a big margin. Misfires will be extremely frequent and will indicate that you need to do a valve job on your car in order to bring the engine performance back to optimum.

This is why whenever you experience misfires, you should always check your rockers and tighten them if you notice that some of them are really loose.

4. Poor Acceleration

The fourth symptom of a bad rocker arm is poor acceleration. If the valves do not function right and you get misfires all the time, you can expect some poor acceleration from the engine as well.

The 4 stroke process will not be perfect. Resulting in misfires. These misfires can be premature or delayed explosions. The timing means that is off on that cylinder. And also there will be a considerable performance loss from running the engine like this. That’s why you need to inspect the valves and rockers and see if they need some tweaking.

The rods are also good to be checked if you want to make sure that you don’t have some of them bent.

5. Visible Damage To The Rockers

And the last symptom of a bad rocker arm that is a possibility is the situation when there is visible damage to the rocker.

If you decide to remove the valve cover and you see how the rocker is missing a piece, this might be the problem that you are looking for. Even though this happens rarely. One in a million times. But still, there could be a chance for something like this. Now let’s cover the rocker arm replacement.

Rocker Arm Replacement

We have covered the symptoms, now let’s learn about the rocker arm replacement. How this work is done?

In order to do this work on your car, you will need to purchase a kit for your specific vehicle. Usually, when one is bad, others will follow and it is advised to replace all of them.

There are kits out there, especially if you own an LS engine. You can get all of the rockers along with new rods and bolts. Replacing the lifters will also going to be an excellent idea since you are already there.

For this rocker arm replacement, you will need to remove the valve cover and the intake manifold. Then carefully remove all of the rockers one by one as well as the lifters.

Install the new hardware and make sure that you torque everything up to spec. In addition to this, make sure that you have the right clearance between the rocker and the valve tips. For this, you will need a feeler gauge to make sure how much you need to tighten your valves.

Overall, the replacement of these rockers is really simple. But still, it needs to be done professionally and according to the manual. Anything else will prevent the engine from working properly. That’s why you need to do your research before you jump into this adventure.

Cost To Replace Rocker Arm

So, what is the cost to replace the rocker arm? The answer to this question really depends a lot on what you are after.

If you just want to replace one damaged rocker, you can purchase one for $15 or even less. If you decide to go for new rockers on your car and want to get something new, then you can expect to pay somewhere in the range of $250 to $350.

And if you decide to replace the pushrods in the process, then the cost for this will be about $500 for the full kit for your engine.

Just take note that prices might vary from manufacturer to manufacturer and some kits can be more expensive than this, especially if we are talking about aluminum rockers for high-performance engines.

Other Problems With Rocker Arms

Now as we covered the rocker arm assembly and the replacement. Let’s focus on some other aspects. More precisely a problem with Honda and Chrysler’s engines concerning the rocker arms

Rocker Arm Actuator (Rocker Arm Solenoid)

Now let’s get into the first problem. And that is the problem with the rocker arm actuator or solenoid on Honda engines.

There are a lot of people that have a problem with the actuator on the rocker arm. This problem is mostly affecting the 2.4L Honda engine. The models that are affected are models built between 2003 and 2011. The models affected are the Accord, Civic Si, CR-V, CR-Z, Element, and Fit.

The code for the problem is P2646 and the definition for the problem is Rocker Arm Actuator Stuck On Bank 1. This means that you have a problem with the first bank of your engine.

This problem is in most cases caused by a dirty VTC strainer that clogs up with oil and malfunctions the actuator.

What you need to do in this case, is to clean or replace the strainers as well as replace the rocker arm actuator with a new one. This component is also called a solenoid or a switch. Basically, it is the same thing. So, beware of this problem if you want to purchase a 2.4L Honda engine from these years of production, they know to have problems with these actuators.

3.6 Pentastar Rocker Arm Recall

Now let’s discuss another problem that is connected with the rockers and this is the problem with the 3.6L Pentastar rocker arm recall.

More precisely, the Pentastar was a new engine that was introduced by Chrysler when FCA took over Chrysler and its sub-brands.

This engine was equipped in many different products in Chrysler, Jeep, Dodge, as well as RAM vehicles.

The most problematic years for this engine were the years between 2014 and 2020. All of the models that come equipped with this type of engine are affected by all of these marques.

The problem was with the rocker arm on the engine itself. These components have failed, more precisely the rollers on the rockers wear prematurely on these engines.

Then as the rocker wears off, and then they become loose and drop. This will make the arm go out of alignment and cause a lot of damage inside of the head.

Causing a ton of metal debris inside and scraping the whole engine head or the whole engine in the process. This means that you will need to get a new engine head if your engine faces this problem.

Which will result in a lot of money spent on repairs. This is why there was a 3.6 Pentastar rocker arm recall lawsuit for this problem. But there are not yet any decisions on it as we understood from reports on CarComplaints.com.

The important thing for you if you have a car that is affected by this problem is to make sure that you change your oil regularly. Since irregular oil changes increase the wear and tear inside of the engine and will make these rockers fail.

Do I Need Valve Adjustment?

Now let’s see if you need a valve adjustment when installing a new rocker on your car. And the answer to this question is yes.

Even if you don’t do a rocker replacement, it is often advised to adjust the valves to make sure that there is enough clearance between the rockers and the valve tip.

You can do this at home using a valve adjustment tool. Another thing you will need is to get a feeler gauge and learn the right valve clearance for your engine. Then you can use this tool to tighten the valves up to spec.

And by doing this, you will sort out the symptom that includes the ticking noise coming from the valve cover. Your valves will be tightened and everything will work as it should from the factory.

Or even if you don’t want to pay for tools and feeler gauges you can do a simple trick. And that is to remove the valve cover when the engine is working and then tighten up the valve until the sound disappears. This is a small mechanical trick, so don’t tell anyone. Now let’s conclude this article.

Facts about Bad Rocker Arms and Replacement Costs

- A bad or worn rocker arm can cause significant engine problems or unexplained noises.

- Clicking or ticking noises are the most common symptoms of a bad rocker arm, but it can also cause misfires or a stalling engine with a check engine light on your dashboard.

- To diagnose a broken or worn rocker arm, you need to remove the valve covers and see what’s going on underneath.

- The rocker arms lift your exhaust and intake valves to allow air to enter and exit the combustion chamber at the appropriate time.

- Rocker arms are located at the engine head, connecting the camshaft to the exhaust and intake valves, and are positioned directly over the engine’s heads.

- The cost to replace a single rocker arm is typically between $500 to $1,500, with almost all of the cost being for labor.

- It is recommended to replace all the gaskets associated with the valve covers and drain the oil, and to replace all the rocker arms at the same time as they tend to wear out at a similar rate.

- Most rocker arms do not need to be replaced often because the hydraulic lifters control wear, but if one is damaged, it needs to be replaced.

- It is not recommended to attempt to replace rocker arms on your own due to the labor-intensive and technical process.

- If you suspect a broken rocker arm, it is important to rule out external causes before tearing apart the engine to look for internal issues.

Conclusion

In this article, we have covered everything about when it comes to the rocker arm. First, we learned what these components are and what they are doing. They are a bridge between the pushrod and the valve.

Then we have covered the symptoms associated when it comes to these components and how to recognize when you have problems with the rockers.

After we covered the replacement and the cost involved in this work. Lastly, we discussed the two most common problems with cars concerning these rockers.

F.A.Q

Now let’s answer some frequently asked questions.

What Is A Rocker Arm

A rocker arm is a valvetrain component on internal combustion engines. This component is basically a bridge between the pushrod and the valve tip. It transfers the motion from one component to the other component and keeps the combustion process working.

What Does A Rocker Arm Do

The rocker arm is basically a leverage component. It transfers the motion from the pushrod to the valve tip. The pushrod basically pushes the rockers and then the valves open. Then when the pushrod releases the pressure the valves close. Everything in this process happens in a fraction of a second.

What Causes Rocker Arm Failure

In most cases, the rollers wear off in some models that include rockers with rollers. Usually, if you have a car that is running without rollers, you don’t have to worry about wear on these components.